Extensively equipped with state-of-the-art equipment, see our manufacturing capacity and general capabilities to discover how we manage the entire fabrication process. From initial concept design to powder coating and assembly, we partner with our customers to deliver quality sheet metal manufactured products across a range of market sectors.

We are ISO 9001:2015 quality accredited and have a highly-skilled team on hand to assist in the operation of our specialist equipment. So, you can rest assured that your products will be designed, manufactured, finished and delivered to the highest standard.

General capabilities

Facility

60,840 sq. ft. of manufacturing facilities

3D Design

10 x Solidworks 2018 3D

Vehicles

2 x 7.5t Lorry

1 x 3.5t Van

1 x Courier Van

4 x fork lift trucks

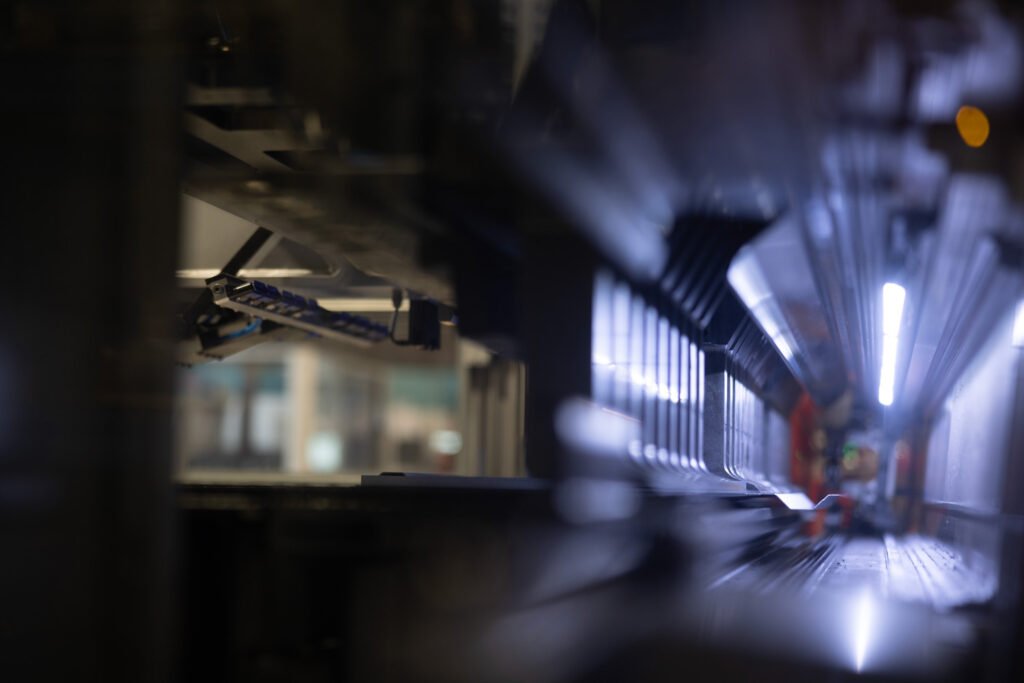

Manufacturing capacity

CNC Punching / Laser Cutting

Amada REGIUS-3015AJ Fibre Laser Profiling Centre with AS LUL-3015 loading system

Amada FOL-AJ 4 kW Fibre Laser with ASLUL loading system

Amada Punch Laser Combination (EML2515 AJP 3 kW) with MPT turret with 4 tapping station, automatic tool changer, and 3t load/unload system with integrated part picking

Amada Punch Laser Combination (EML3610NT 4 kW) with MP 6t loading system with tapping head

Amada Automated Punching (AE2510 NT) with SheetCAT loading system

Amada Togu III Auto Tool grinding

Press Brakes / CNC Folding

2 x Salvagnini P2 Panel Bender

1 x Amada HRB-1003ATC 3M Press Brake (with Automatic Tool Changer) (100t)

2 x Amada HFE 3I 2M Press Brake (50t)

2 x Amada HFP 100x30NT 3M Press brake (100t)

1 x Amada HFP 170x40NT 4M Press brake (170t)

1 x Amada HFE 2.5M Press Brake (80t)

1 x Amada EG 4010 1M Electric Press Brake (40t)

Extensive range of tooling

Inserting

2 x Haeger 824 WindowTouch 5e fastener insertion system

Powder Coating

Automated Gema MagicCompact® powder coating plant with in-line pre-treatment

OptiCenter® OC02 with OptiFlow IG07

6 x OptiGun® Automatic guns

2 x OptiSelect® Manual stations

MagicControl 4.0 (CM40) system control

Additional booth and box oven capacity for larger items

Assembly Facilities

Dedicated assembly area

Large range of fixings and fasteners carried as stock

Welding

MIG/TIG welding facilities (12 Welding Stations)

Spot welding

Laser welding: Max Photonics ZXMA1-65 handheld system with wire feed (up to 5.5 mm aluminium / 6.5 mm steel variants)

Robotic welding: Six-axis Fanuc ARC Mate 110iC (twin cell set up)

Robotic welding: Six-axis Fanuc AM100id (R30ib mate controller), with a Kemppi 350A A7 MIG welder and Binzel torch system

We’re proud of every product we make

Stay ahead of the competition, utilise our wide range of services and get your products to market with ease.