Delivering the benefits of metal punching services since 2007

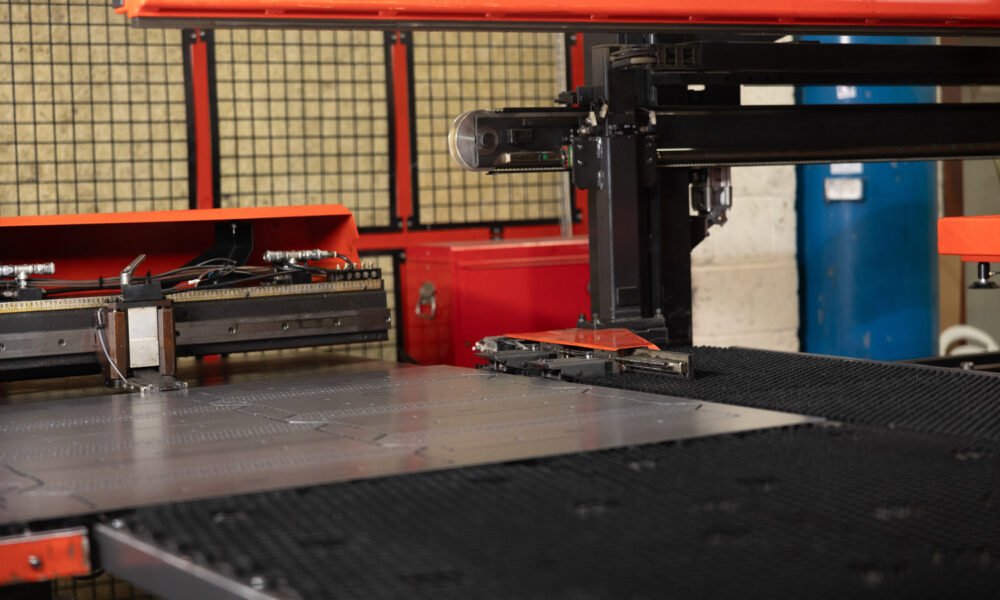

Our CNC punching facility, equipped with high-speed Amada CNC punching machines, excels at producing medium to high volume runs of repeating punched parts with repeating detail. And, with automated ‘lights-out’ abilities customers benefit from exceptional productivity, efficiency and cost-effective manufacturing, making us the ideal partner for metal punching services.

Exceptional efficiency and output in metal punching

Automation is key in maximising output and efficiency in production. Here at Unifabs, we integrate our CNC punching machines with automated load/offload cells to optimise production.

CNC punching services for sheet metal manufacturing

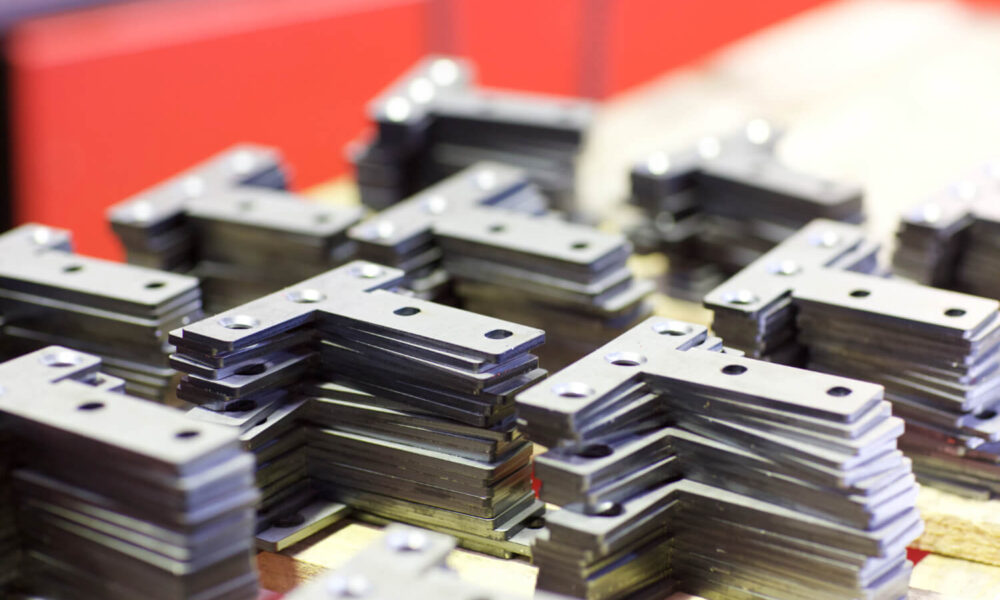

In addition to using CNC punching to create flat components, our skilled operatives support the production of 3D forms, including louvres, dimples, embossed logos, and features. We also perform tapping and countersinking in situ, delivering high-quality, precision components.

We utilise the most appropriate, cost-effective and efficient method of manufacture for your product. With the punch/laser combination at Unifabs we are able to deliver unmatched performance, punching, forming, tapping and laser cutting on one machine, eliminating the need for secondary profiling operations.

Our metal punching services are often the starting point for many jobs utilising our full range of manufacturing services. Get in touch today to discuss how we can support your sheet metal product requirements.

Materials

- Mild Steel

- Stainless Steel

- Aluminium

- Pre-Galv

- Zintec

Capabilities

Sheet size

3000 x 1500 mm

Material thickness

up to and including 3 mm

Technology

- Amada Automated Punching (AE 2510 NT) with SheetCAT loading system

- Amada Punch Laser Combination (EML 3610 NT 4 kW)

- Amada Togu III Auto Tool grinding

Our CNC Punching Capabilities

Our metal punching services offer the very best in punching technology for reliability, flexibility and quality.

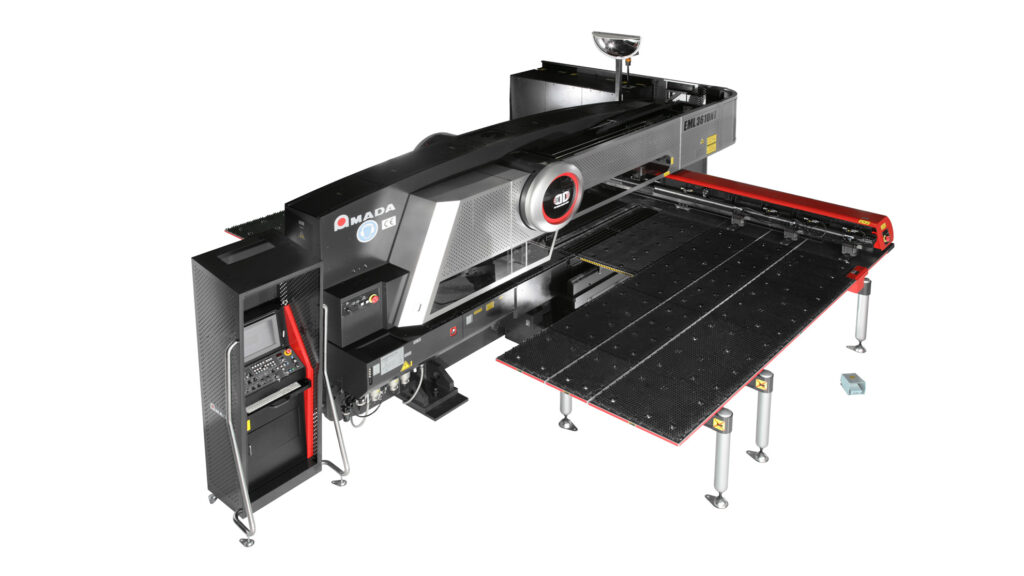

Amada Punch Laser Combination

EML 3610 NT 4 kW with MP 6 t loading system with tapping head

Incorporating the latest advances in punching and laser cutting technology, the EML NT combines Amada’s revolutionary EM (Electric Motor) punching technology with the reliability of Amada’s hybrid laser motion system. The result is one of the most productive fabricating machines on the market delivering unequalled precision and flexibility.

Amada Automated Punch Press

AE 2510 NT with SheetCAT loading system

Amada's AE-NT turret punch press features a large capacity turret in a small footprint, delivering stable, high-speed, high quality processing of the most demanding production requirements.

Amada Togu III Auto Tool Grinding

We understand the importance of tool maintenance to ensure the finest quality punched parts. The Amada Togu is the perfect accompaniment to support our CNC metal punching services. The automatic tool sharpener purposely designed for high quality sharpening of sheet metal tools keeps them in optimal condition, maximises tool life and ensures quality punched holes.

Everything you need to know about CNC Metal Punching

Here is an overview of questions that we are most commonly asked.

Want to learn more?

The process of creating a hole or form in a sheet of metal by applying enough force to either create an indent or sheer through the material. A die, located underneath the sheet metal, contains the cutout of the shape required. The punch press forces the punch downward at high speed through the sheet metal and into the mating die below. This process can be performed utilising a manual punch press but more commonly CNC punching machines are used today.

A wide variety of materials can be used in CNC punching machines; from metals like steel and aluminium to plastic, wood and more.

CNC punches are versatile. Punched holes are typically simple geometric shapes for example a circle or rectangle but more complex shapes or patterns can be produced by using multiple hits and tools, overlapping geometries or through custom tooling for more specialist requirements, making CNC punching a flexible and cost-effective method of sheet metal manufacture.

We’re proud of every product we make

Stay ahead of the competition, utilise our wide range of services and get your products to market with ease.