Design is more than aesthetics. We help you to create individual parts and products that perform, fulfil their purpose and look the part, whilst being manufacturable and cost effective to produce.

Design for manufacture (DfM): Turning concepts into reality

Not only do we design creatively and with an open mind, but we also carefully consider the ‘how’ at every stage. Unlike pure product design companies and in-house engineering teams, we fully understand that we will ultimately face the challenge of manufacturing our designs. Therefore, we ensure that our design process is both innovative and practical, balancing creativity with the realities of production.

This is why our approach is firmly rooted in design for manufacture.

Design for manufacture and assembly (DfMA) process

Our in-house engineering design team specialises in all aspects of sheet metal manufacturing, and we work closely with you to design parts that are fully prepared for mass production and assembly. With our expertise, we ensure that every design is optimised for efficient manufacturing, helping to streamline the process from concept, through manufacture and assembly, to completion.

Not only can we design for our own in-house processes, but we can also seamlessly accommodate outsourced processes such as PU mouldings, machined components, and textiles. This flexibility ensures that, regardless of the production method, our designs are optimised for efficient manufacturing.

Primed for prototyping

With in-house 3D printing technology and manufacturing equipment dedicated to R&D, we provide rapid prototyping to our clients. This enables us to quickly test, prove out and refine component parts, ensuring optimal performance without the delays of sourcing or manufacturing external components, making the entire process not only faster but also more cost-effective.

Let’s bring your product to life with a design that’s ready for production. Speak with our experts now to discuss your requirements.

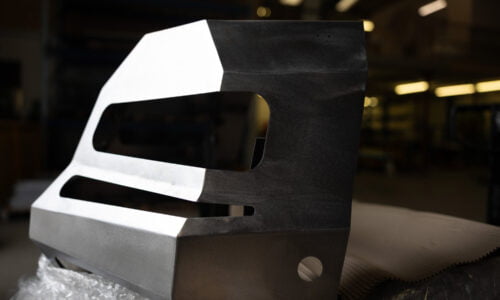

Design for manufacture in action

We have numerous examples of our design for manufacture (DfM) process delivering real-world results for clients across various industries.

One such case is our work with McConnel Ltd., where we developed a rear casing for their agricultural machinery. This project highlights our ability to design parts that meet functional requirements while being cost-effective and ready for mass production.

Explore this case study and many more to see how we turn innovative designs into manufacturable realities.

Visit the Knowledge Base

Uncover more about sheet metal manufacturing processes, delve into our industry insights, and find answers to your frequently asked questions in the knowledge base.

Optimised designs help products thrive

Contact us today to discuss our design for manufacture process and your design requirements.