Introduction

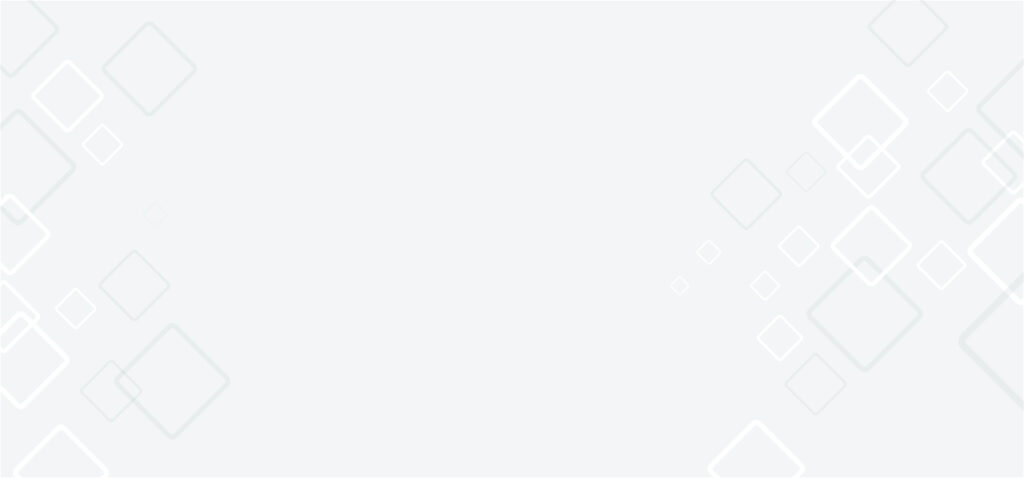

At Unifabs, our powder coating service is more than just applying a finish — it’s about delivering a consistently high-quality, durable coating that meets the exacting standards our customers expect. Central to achieving this is a rigorous inspection process, including detailed cross-hatch adhesion testing, which ensures every component we coat performs reliably throughout its service life.

Why Inspection Matters in Powder Coating Services

Powder coating is widely valued for its durability, corrosion resistance and excellent aesthetic qualities. However, these benefits depend heavily on precise surface preparation, controlled application technique and thorough quality control.

Our inspection protocol ensures that each coated part is scrutinised to identify any defects before it leaves our facility. Under good lighting and observed from a distance of 1 metre, coatings must demonstrate uniform colour and texture without issues such as picture framing, runs, excessive build-up, pinholes, inclusions, craters, dull spots or scratches. Thickness measurements are taken at five different points using calibrated gauges, with an ideal average range of 60–120 microns. This thickness is vital to both protection and adhesion, ensuring the coating withstands wear and environmental factors over time.

Cross-Hatch Testing – A Key Adhesion Check

Adhesion testing is one of the most critical elements of our powder coating inspection process. The cross-hatch test is standardised by organisations such as ISO (ISO 2409) and ASTM (ASTM D3359). At Unifabs, we utilise the ISO 2409 cross-hatch adhesion test, the industry standard across the UK and Europe, to verify how securely the powder coating adheres to the substrate.

Cross-hatch adhesion test procedure:

- Cutting the lattice – Using a specialised cutting tool, a lattice pattern of parallel cuts is made through the powder coating and down to the substrate. A second set of parallel cuts is then made perpendicular to the first, creating a grid or checkerboard pattern. The number of cuts and their spacing are determined by the coating’s thickness.

- Removing debris – A soft brush is used to gently remove any detached flakes or loose particles from the cuts.

- Applying and removing tape – A specific pressure-sensitive tape is applied firmly over the cut area. The tape is smoothed down to ensure good contact with the surface. After a short time, the tape is removed quickly at a specific angle (often 180 degrees).

- Rating the adhesion – The cut area is then visually inspected and graded according to the ISO 2409 classification scale. The degree of flaking or coating removal determines the final adhesion rating.

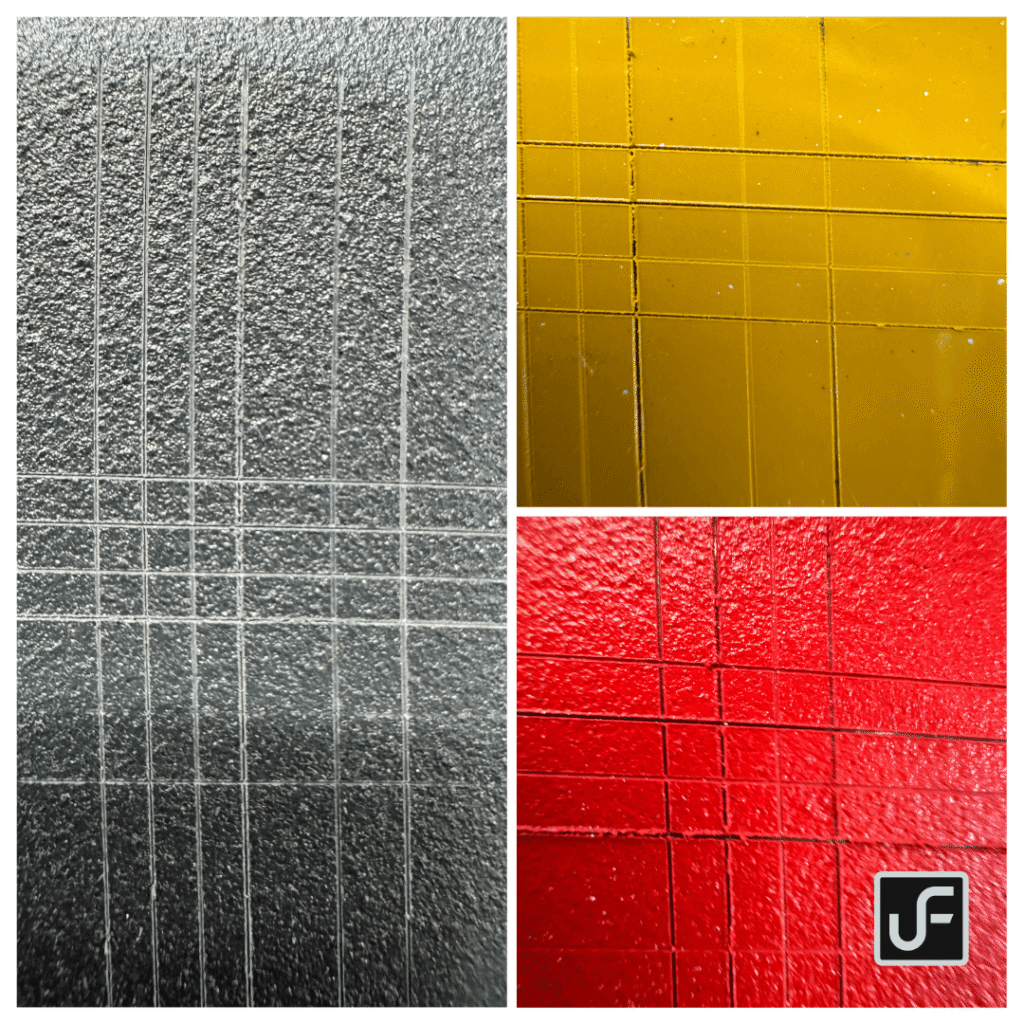

Understanding the ISO 2409 Rating System

The results are typically rated on a scale to indicate the quality of the adhesion. The specific rating scale can vary between standards (e.g., ISO and ASTM), but they represent a similar pass/fail threshold. ISO 2409 results are rated from Class 0 (best) to Class 5 (worst):

Class 0 – No flaking or detachment; perfect adhesion.

Class 1 – Small flakes detached at cut intersections, affecting no more than 5% of the lattice area.

Class 2 – Flaking along edges and intersections affecting more than 5% but up to 15%.

Class 3 – Flaking affecting 15–35%.

Class 4 – Flaking affecting 35–65%.

Class 5 – Severe flaking over more than 65%.

At Unifabs, Class 1 is our minimum acceptable adhesion standard, allowing only very minor flaking that does not compromise the coating’s integrity or performance — a threshold aligned with the demands of industrial powder coating applications.

ASTM D3359 Comparison

The US-based ASTM D3359 adhesion test is similar but uses a reversed scale from 5B (perfect adhesion) down to 0B (complete failure). ISO Class 0 roughly equates to ASTM 5B, while ISO Class 1 corresponds approximately to ASTM 4B. This comparison helps those using the ASTM system understand how our UK-based testing aligns with their own standards.

Colour Consistency and Visual Quality Control

In addition to adhesion and thickness, colour accuracy is verified using calibrated colour analysers. Random samples are compared against industry databases (such as e-paint.co.uk) to ensure consistency from batch to batch. Our minimum standard corresponds to a colour difference discernible only to a trained eye, ensuring client expectations are met without unnecessary rejection of acceptable variations.

Why Choose Unifabs for Your Powder Coating Service?

While powder coating is an inherently industrial process — not a wet spray finish — our meticulous coating, inspection and testing procedures guarantee a finish that is both visually appealing and built to last.

Whether you are at prototype stage or a full production run, Unifabs combines precision, rigorous quality assurance and extensive experience to deliver powder coating services you can trust. You can see examples of our powder coating work in our case studies or learn more about our full fabrication and manufacturing service offerings.