Challenge

The Bentley brand is synonymous with luxury automotive craftsmanship, craftsmanship which needed to be well protected in transit. Bentley approached Unifabs to create a custom stillage design to accommodate two front end modules in as small a footprint as possible. The custom stillage design needed to be robust enough to protect the modules in-transit to Europe. It also needed to be capable of interfacing with a lift assist system to present the module to the car line side.

Solution

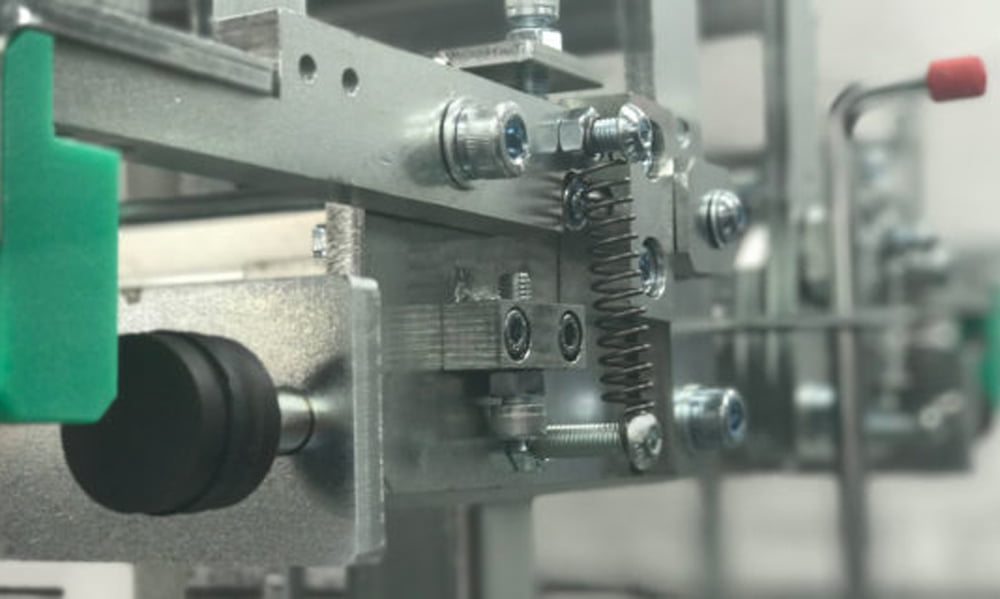

After closely consulting to understand the line-side requirements, Unifabs’ industrial design team drafted an initial concept of a rotating stillage. They manufactured and assembled a prototype capable of rotating the module within the stillage, then further refined it to provide an effective solution.

Result

The prototype minimised footprint whilst offering maximum protection in transit and usability at line side. An initial 15 units were produced to aid production with a further 160 units ordered.

Team Feedback

Prototyping enables us to prove out components and designs, allowing for refinements to be quickly made and tested. This step in the design process is particularly useful when products integrate with other systems.

Project Manager

Services & Solutions from this project

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.