Challenge

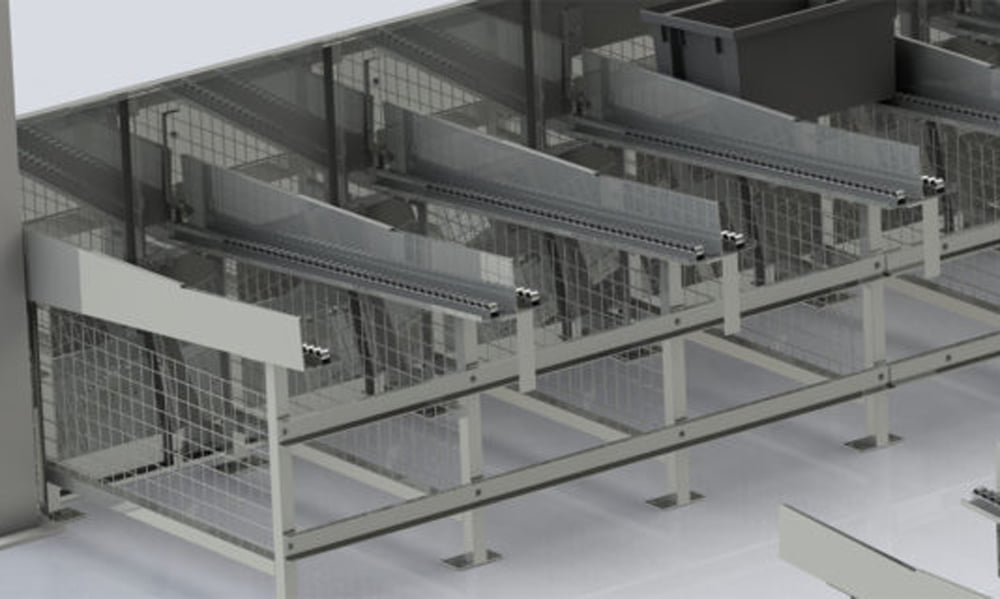

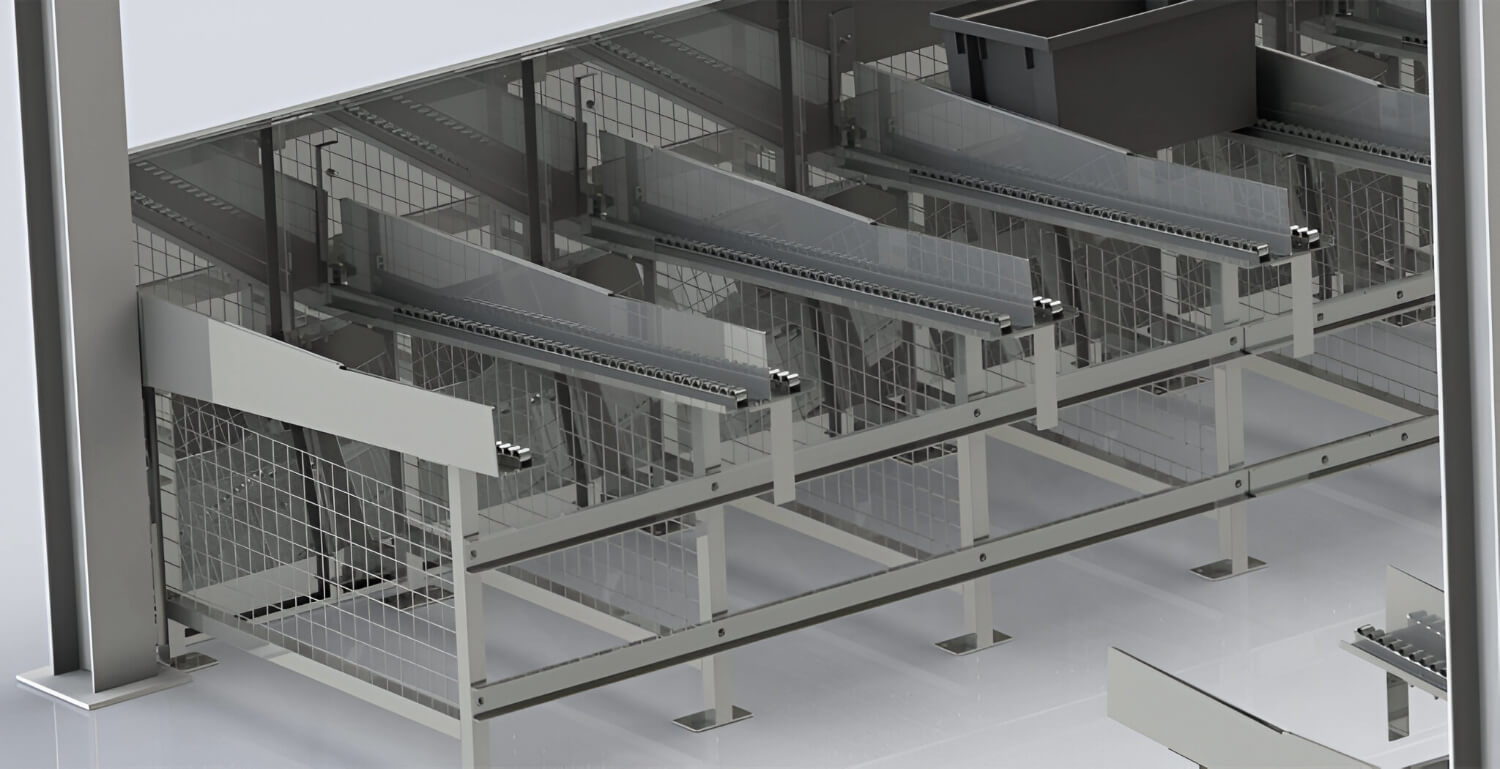

To develop modular tote load/unload stations able to handle totes up to 50 KG. The system was required to interface with an existing automatic tote picking system.

Solution

After close consultation with the customer to understand the interface between the tote picking system, Unifabs proposed a specification for the system, and subsequent concept and full manufacturing drawings. A prototype bay was manufactured and performance tested.

Result

The customer was very happy with the installation, which fully fulfilled their brief and resulted in 130 stations being manufactured in total. By designing modular tote load/unload stations that integrate seamlessly with automated picking systems, this project demonstrates our expertise in efficient warehousing and logistics solutions and material handling within modern facilities.

Team Feedback

Our industrial design team utilises their cross industry expertise to produce full concept designs to meet exacting requirements.

Project Manager

Tote load/unload stations

Key facts

- Industrial design service

- Full concept design

- Modular system design

- Requirement to interface with existing systems

- 130 off manufactured