Form your future

Manufacturing is an innovative, ever-evolving industry that offers a vast range of career options. And with the skills shortages in the UK, there is no better time to start an engineering apprenticeship in manufacturing and fabrication.

Passionate about the next generation

At Unifabs we are passionate about investing in the next generation.

We firmly believe that apprentices are the future of our business.

So, we have created the ‘Unifabs Academy’ in association with Birmingham based Train’d Up, in order to keep new talent coming into the business, and keep British manufacturing alive.

We don’t stop at just engineering apprenticeships, we also offer apprenticeships across a range of business functions.

What do we offer?

We are proud to offer engineering apprenticeships from Metal Fabricator Level 3 and beyond.

Working in partnership with Train'd Up, our engineering apprenticeship program includes both remote-based lessons, and hands-on training, learning from highly trained experienced engineers at Unifabs, using our state-of-the-art equipment. Remote learning, practical work and assessments all take place in the workplace.

What are the benefits of an engineering apprenticeship at Unifabs?

At Unifabs Academy, we offer Engineering Apprenticeships that provide hands-on training in a supportive environment. You’ll gain high-quality, real-world experience and develop a wide range of skills to launch your career.

We keep our apprenticeship intake small, giving you plenty of one-to-one time with industry experts who will guide you throughout your training. When you complete your apprenticeship, we’ll offer you a full-time position at Unifabs with exciting opportunities for career growth within our expanding business.

What will we expect from you?

Apprentices are expected to work to a standard required by the national curriculum and Unifabs. Your work will be observed by internal training staff and there may also be some studying involved in your own time.

What will you learn?

Unifabs has a dedicated Academy training area where successful candidates will learn and practise the full range of manufacturing processes, including:

- Interpreting manufacturing drawings, tolerancing and manufacturing symbols.

- CNC laser/punch programming/nesting, operation and in-process inspection.

- Press brake/metal bending, setting, operating and in-process inspection.

- MIG, TIG and spot welding, and fabrication including drilling/tapping/countersinking, sawing, in-process inspection, and jigs and fixtures.

In addition to learning the above during your course, you will also learn about powder coating (loading efficiently, pre-treatment, robot line, manual booth and calibration), and mechanical assembly including the use of assembly tools, interpretation of assembly drawings, use of non-metallic materials and packaging. This covers the full range of services offered at Unifabs.

Meet the Unifabs apprenticeship team

Our Apprenticeship Team is led by Matt Grealy, our Technical Director, who brings his in-depth industry knowledge and passion for innovation to every apprentice’s journey.

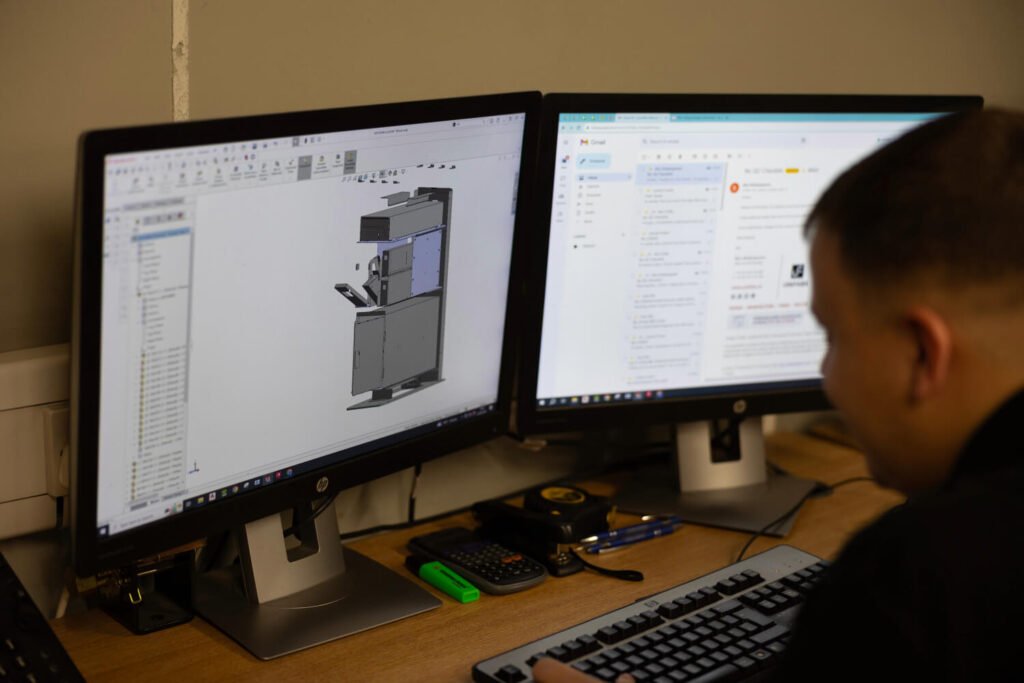

Supported by Ashley Roberts, our R&D Coordinator and CAD Engineer, apprentices gain valuable insights into the design and development processes that drive modern manufacturing. Together with a wider team of specialists in each discipline, this dedicated team is committed to nurturing the next generation of skilled professionals at Unifabs.

Matt Grealy

Technical Director

Ashley Roberts

R&D Coordinator

Apprentice stories and Q&A's

At Unifabs, we love celebrating our apprentices and sharing their experiences. Our Q&A series highlights the journeys of apprentices across different engineering and manufacturing pathways, giving insight into life at Unifabs and the skills they’re developing.

Apply today

If you would like to earn a place on one of our sought after manufacturing apprenticeship schemes, apply today via Indeed at the link below, or contact us for further information.