Introduction

Sheet metal components are widely used in various industries due to their durability, versatility, and cost-effectiveness. One of the primary manufacturing processes involved in creating these components is metal bending.

Metal bending is the process of deforming a flat sheet of metal into a specific shape or geometry by applying force to it. This process is essential for creating complex and customised components used in a wide range of applications.

Here we explore the critical role of metal bending techniques in the design of sheet metal components. Metal bending is a fundamental process used in various industries, such as automotive, aerospace, construction, and manufacturing. Properly executed metal bending techniques are essential for achieving structural integrity, precision, and cost-efficiency in sheet metal products. This article provides an overview of the techniques involved, considerations during design, and the advantages of employing these techniques.

Techniques for Metal Bending

Press Brake Bending

Press brake bending is one of the most common and versatile techniques for metal bending. It involves using a press brake machine to clamp and bend the sheet metal to the desired angle.

Key points to consider for press brake bending include:

- Die Selection: The choice of the die determines the bend angle and radius. Whilst the optimum die may be suitable for the majority of folds, small bends and features close to the bend line may require more thought and different tooling.

- Material Thickness: The thickness of the sheet metal influences the required bending force and the machine’s tonnage capacity, and also what tooling can be used.

- Bend Allowance: Accurate calculation of the bend allowance is crucial for achieving the desired dimensions in the final component.

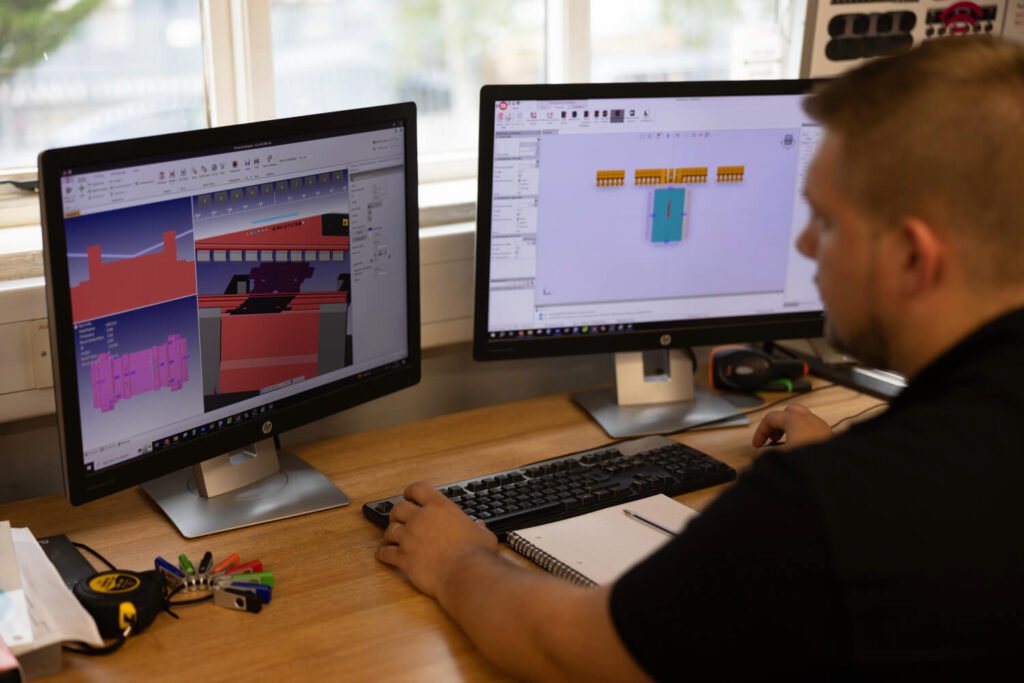

- Tooling Setup: Proper tooling setup, including die selection, punch, and back gauge position, is necessary to ensure precision and repeatability. If the time is spent up-front to optimise this, the machine’s output will be more efficient. Unifabs has recently introduced offline programming integrated into our CAD office. This has proven to have reduced downtime in the bending department.

Incremental Bending

Whilst we have a wide range of radius top tools for our press brakes at Unifabs, sometimes the length of the bend or size of the radius means another method must be used.

Incremental bending, or step bending, is used to create components with a large radius when tooling is uneconomical. It involves bending the sheet metal in small increments with a slight angle, gradually achieving the desired shape. When done correctly the stepped curve appears continuous.

Considerations in incremental bending include:

- Bend Sequencing: Planning the sequence of bends is crucial to avoid distortion and get the smoothest curve.

- Support and Fixturing: Adequate support and fixturing are required to maintain accuracy during the incremental bending process.

- Material Elasticity: The material’s elasticity and its effect on springback must be considered when designing the component to allow the desired final shape to be achieved.

Panel Bending

Automated panel bending machines such as the Salvagnini’s at Unifabs add another dimension to bending capabilities. Whilst offering most of the same capabilities as a press brake such as incremental bending and hems, this is all done by automatic fast changing tooling and manipulation of the part by the machine itself.

Design Considerations

When designing sheet metal components that involve metal bending, several factors must be taken into account for instance:

- Material Selection: The choice of sheet metal material, such as steel, aluminium, or stainless steel, impacts the ease of bending, strength, and corrosion resistance.

- Tolerance and Accuracy: Precise dimensional tolerances must be defined in the design to ensure the component’s functionality and fit.

- Bend Radii: The minimum and maximum bend radii should be considered to prevent material damage or cracking during the bending process.

- Tooling and Dies: Are the tools available to produce the desired bends? If not, could the design be modified to suit existing tooling without compromising the overall part.

- Bend Allowance and K-Factor: Bend allowances should be calculated for all materials, angles and tooling. This is something we have done here at Unifabs for all tooling used in-house. Having these calculations allows us to concentrate on design aspects. It enables us to work from customer models quickly and efficiently, with the correct results every time.

Whilst it is possible to simulate all folding for both press brakes and panel benders offline, sometimes prototypes are required to prove out designs.

For example, it may be that complex bends such as large radius’ related to an uncontrolled bought-in part needs to be trialled. It is important to test these features and learn as much as possible before mass production. Due to this, Unifabs has a dedicated R&D area for prototyping.

Advantages of Proper Metal Bending Techniques

- Cost-Efficiency: Properly designed and bent sheet metal components reduce material waste and labour costs.

- Structural Integrity: Correct bending techniques ensure the structural integrity of components, preventing premature failure.

- Customisation: Metal bending allows for the creation of complex and customised shapes, meeting specific design requirements.

- Efficiency and Precision: Well-planned metal bending processes lead to high precision and repeatability.

- Reduced Lead Time: Efficient metal bending techniques can reduce lead times, making production more agile and responsive to market demands.

Conclusion

Metal bending techniques are a critical component of the design and manufacturing process for sheet metal components.

By selecting the appropriate bending technique, considering design factors, and utilising the proper tools, engineers and manufacturers can create high-quality, cost-effective, and structurally sound sheet metal components. The advantages of employing these techniques include increased efficiency, customisation options, and reduced production costs, making them a key aspect of modern manufacturing.

Effective collaboration between design engineers and metal fabricators is essential to ensure that the chosen metal bending techniques align with design specifications and production capabilities. Continuous improvement in both design and manufacturing processes will further enhance the quality and competitiveness of sheet metal components in various industries.