UK sheet metal fabrication services

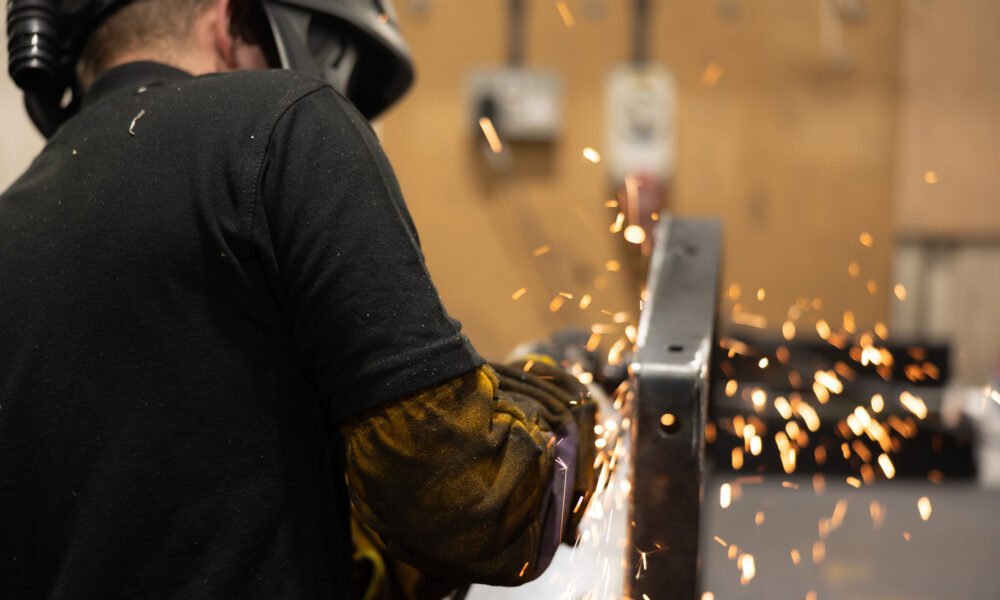

Our Fabrication Centre is where we deliver our welding and fabrication services to turn individual components into welded assemblies, and houses our welding bays, linnishing area, spot welding equipment, laser welding cell and automatic saw.

We specialise in medium to high volume production welding in mild steel, Zintec, aluminium and fabrication of stainless steel.

Whatever your welding requirement we have the expertise and equipment to assist. Working 24 hours per day, our experienced welding team produces high quality sheet metal fabrications for a wide range of applications, ranging from simple to complex, in a variety of sizes, and for an array of market sectors.

Fabrication and welding

We deliver a range of fabrication and welding services including MIG welding, TIG welding, spot welding, laser welding and robotic welding to transform manufactured parts into welded assemblies.

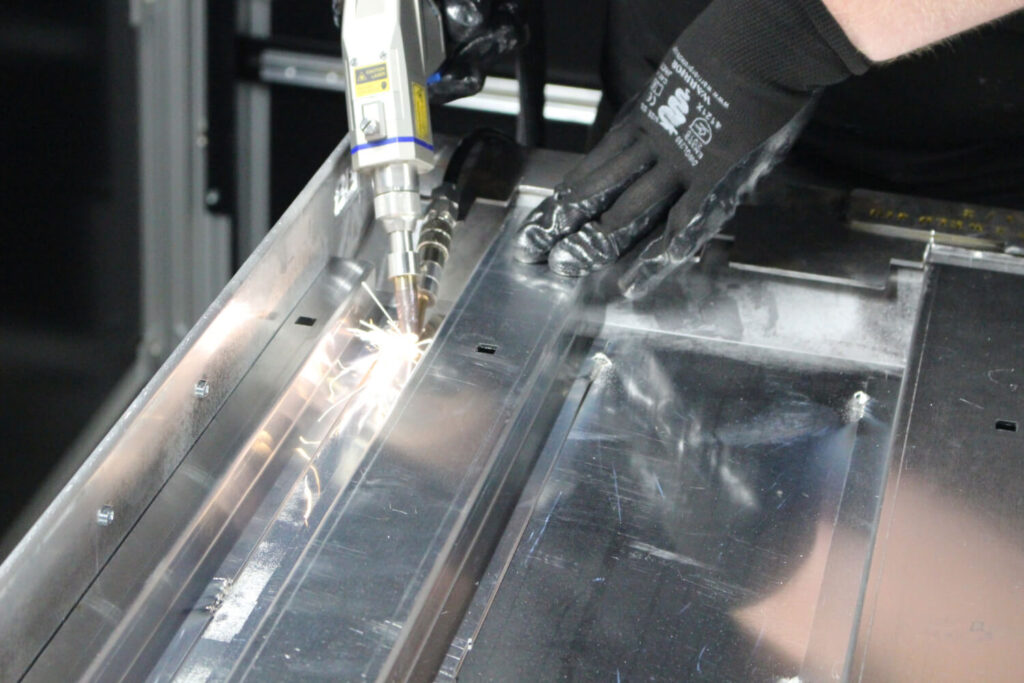

Laser Welding

We have recently invested in advanced laser welding technology. The Max Photonics ZXMA1-65 handheld laser welding system allows us to deliver highly precise, clean welds with minimal distortion, particularly on challenging materials such as aluminium.

Laser welding offers several advantages over traditional methods, including faster processing speeds, superior weld aesthetics, and reduced heat input—resulting in stronger joints and less post-weld finishing. The integrated wire-feed capability expands our ability to work on a variety of joint types and material thicknesses. This addition enhances our fabrication portfolio by providing greater flexibility and quality, especially for applications requiring tight tolerances and high cosmetic standards. Combined with our skilled operators and fully enclosed welding environment, laser welding at Unifabs ensures quality results delivered efficiently and reliably.

Cost effective welding and fabrication services

Although we do offer welding as a stand alone service where required, more often components produced in our Sheet Metal Centre or on our automatic saws feed our Fabrication Centre with parts. Customers benefit from utilising a range of services in turn providing immediate cost-savings.

Materials

- Mild Steel

- Stainless Steel

- Zintec

- Aluminium

Capabilities

Manual & Robotic Welding

Fabrication services for all project sizes and complexities.

Laser Welding

High-precision welding with minimal distortion—ideal for aluminium and fine-detail assemblies.

High Volume Production

Efficient and consistent welding for large-scale orders.

Custom Jig Design

Tailored jigs to reduce set-up times and enhance precision.

Technology

- 12 x MIG/TIG Welders

- Spot Welding Machine

- Laser Welding Cell

- Separate Linishing Area

- Robotic Welding

Our Fabrication & Welding Capabilities

Fabrication services that transform individual components into high quality welded assemblies.

MIG/TIG/Spot Welding

Types of manual welding processes

Our skilled welding team uses different manual welding processes to ensure consistent, high-quality welds that achieve maximum strength, durability and the best appearance. The type of process used is dependent on the product, material and finish required.

Laser Welding

Max Photonics ZXMA1-65 with integrated wire feed

Our handheld laser welding system delivers precision, clean aesthetics, and minimal distortion across a wide range of materials and part geometries. The integrated wire feed allows for a variety of joint types and material thicknesses—handling up to 5.5 mm aluminium and 6.5 mm stainless steel, mild steel, and galvanised sheet. Learn more in our laser welding FAQ's.

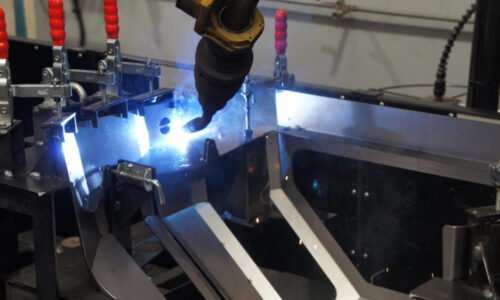

Robotic Welding

Single cell and twin cell robotic welding

Robotic MIG and TIG welding with our Six-axis Fanuc ARC Mate 110iC (twin cell) and Six-axis Fanuc AM100id (single cell) set up delivers cost-effective, high quality, repeatable welding.

Everything you need to know about Welding

Here is an overview of questions that we are most commonly asked.

Want to learn more?

In simple terms, welding is the joining together of two parts using a filler material and heat. The filler is heated until it melts and pools between the two objects resulting in a strong join between the parts.

MIG welding (metal inert gas welding) is the process of joining pieces of metal together through the use of electricity. An electrical arc is created between an electrode wire and the metal that is being welded. The electrical arc melts the wire which pools between the two pieces. Once it has cooled it solidifies and the weld is created. At the same time, a shielding gas is used to protect the weld pool and remove any atmospheric gases that would weaken the weld. MIG welding is a fast and versatile method suitable for joining a variety of metals of thin to medium thicknesses.

TIG welding (Tungsten inert gas welding) is another process of joining metals together through electricity. An electrical arc is created between a non-consumable tungsten electrode and the metal being welded. The high melting point of tungsten electrodes means that they don't melt during the process. Instead the arc melts the metal being welded along with a separate rod of filler metal to form a weld bead. At the same time an inert shielding gas (typically argon, an argon mixture or helium) is used to protect the weld pool from the air. Once the heat is removed the pool cools and solidifies and the weld is complete. This clean and versatile welding method is suitable for a wide range of metals. TIG welding is good for tricky shapes and corners, where welds will be visible, or where finish is important.