Robotic arc welding services

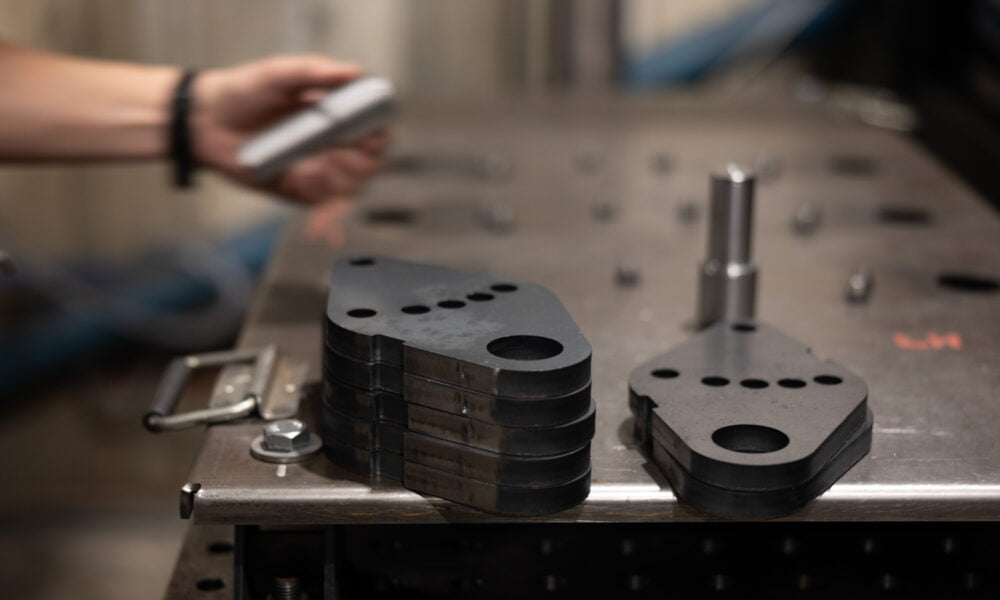

Our robotic welding systems allow us to manage our scheduled, ongoing subcontract manufacturing work with ease. By using robotic arc welding technology, we are able to improve the quality, repeatability and speed of the welded products we produce for our OEM customers, and keep costs down.

What is robotic welding?

In basic terms, it is where the welding process is automated through the utilisation of robots. The robots perform the welds required based on a program, however operators still control and manage the process. This technology allows for fast and precise welding, and enables welding of complicated and difficult to access locations. Robots can adapt to a variety of welding processes through accurate programming and the use of jigs integrated with the robot to aid production.

Advantages of robotic welding

Robotic welders have the unique capability of being able to produce high volume, constant and repetitive welds of exceptional and consistent quality. Robotic welding systems are accurate and produce less wasted materials and time when compared to manual welding.

There are also significant advantages from a health and safety perspective. With manual welding comes a number of hazards (fumes, sparks, heat etc.) which are vastly reduced through the use of robotics, protecting our employee’s safety and wellbeing.

Unifabs operate a twin cell layout which carries its own advantages; the robot can serve either one or both stations. This enables jigs or the next job to be set up in one cell by an operator, whilst the robot is busily welding in the other. This maximises throughput and efficiency whilst reducing labour costs.

Materials

- Mild Steel

- Aluminium

Capabilities

Max fabrication size

3000 x 1500 mm

Max fabrication weight

1000 kg

(for manipulators)

Technology

- Six-axis Fanuc ARC Mate 110iC (twin cell)

- Six-axis Fanuc AM100id (single cell)

Our Robotic Welding Capabilities

Our robotic welding services offer the very best in cost-effective, high quality repeatable MIG and TIG welding.

Robotic Welding Technology

Six-axis Fanuc ARC Mate 110iC (twin cell)

The ARC Mate features a high rigidity arm and advanced servo technology increasing motion speed and decreasing cycle times, delivering on productivity and repeatability. Mounted on a 9 m track servicing two 3 m single axis manipulator stations, the ARC Mate 110iC at Unifabs can be busy welding in one cell, whilst the operator is setting up the other.

Six-axis Fanuc AM100id (single cell)

The Fanuc AM100id robot can handle a wide variety of welding tasks. Its slim curved design, integrated features and larger workspace allow for a bigger working range. This is combined with a Kemppi 350A A7 MIG welder and Binzel torch system, producing a powerful combination that delivers consistent precise results.

Visit the Knowledge Base

Uncover more about sheet metal manufacturing processes, delve into our industry insights, and find answers to your frequently asked questions in the knowledge base.