We provide far more than just the manufacturing of individual sheet metal components. Our comprehensive sheet metal manufacturing solutions are designed to add value at every stage of the process, helping you to bring your products to market efficiently and effectively.

Sheet metal manufacturing solutions to support you.

From initial conceptual designs produced by our in-house sheet metal engineering design team to fully finished, assembled and packed products ready to ship directly to your client, we are here to support you every step of the way. Our goal is to integrate seamlessly into your operations, providing manufacturing solutions that enhance your products’ performance and market appeal.

We pride ourselves on being more than just a supplier—we aim to be a true partner in your product’s success. Whether we’re working with you to refine your design from its earliest concept or optimising your designs to reduce costs and improve efficiency, we have the expertise, technology, and resources to meet your needs.

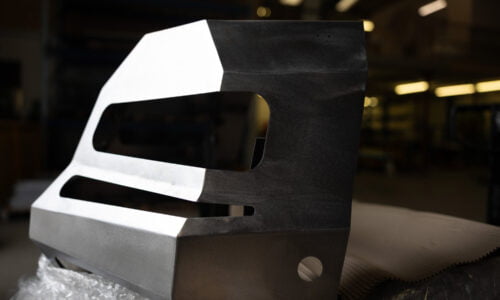

With a broad range of sheet metal engineering solutions in-house, whether it’s a simple fabricated component that you need designing or you have more complex requirements, you can trust us to deliver quality products that meet the highest standards.

At the core of our approach is a commitment to quality and innovation. We continuously invest in the latest technology and manufacturing techniques, ensuring that our processes are at the cutting edge of the industry. This dedication to excellence means you can trust us to deliver consistent, high-quality results that keep your projects on track and to budget.