Looking to lower production costs without sacrificing quality? At Unifabs, we specialise in value engineering services, helping you create products that are cost-effective, efficient to manufacture, and meet or exceed your functional requirements. Our value engineering services deliver real cost savings without compromising on performance or durability.

Delivering the benefits of value engineering

Our in-house team of industrial engineers is dedicated to supporting you in finding the best solutions. We help you uncover hidden savings by reviewing both new and existing designs to determine if a product could be manufactured in a more cost effective or efficient manner.

This review process, known as Value Engineering, often reveals opportunities for cost reductions through the utilisation of different materials or manufacturing techniques.

Benefits of our approach include:

- Lower Production Costs: Reduce material and labour expenses while maintaining product performance.

- Increased Efficiency: Streamline production methods for faster turnaround and reduced lead times.

- Enhanced Product Quality: Ensure products perform reliably through improved design and materials.

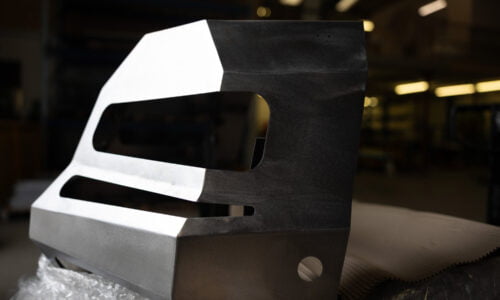

Our engineers aren’t solely focused on reducing costs; they are also constantly seeking innovative ways to enhance the performance and functionality of your products. We tackle complex design challenges by thinking outside the box and finding creative solutions that lower costs without compromising quality, such as in this example of a component for an agricultural machine.

Adding value through design

Our value engineering approach is built on deep technical expertise and a commitment to finding the most efficient solutions for our clients. Our technical design department possesses extensive experience in all manufacturing methods at our disposal and more. We review product designs with an open mind, thinking creatively to generate ideas that enhance value.

This process often reveals methods to produce products more cost-effectively without decreasing functionality or reducing life-cycle. Strategies such as removing redundant features, altering the order of the manufacturing process, or suggesting material changes can all lead to reductions in production costs.

We don’t simply hand over solutions; instead, we work closely with your team at every stage. Whether tweaking an existing design or creating a completely new one, we ensure our suggestions align with your goals, keeping you involved throughout the process.

Ready to reduce costs and optimise your products? Speak with our value engineering experts today to explore how we can help improve your designs without compromising on quality.

How we achieve cost savings

1. Material Substitution

By carefully selecting alternative materials, we lower material costs without sacrificing strength, durability, or performance. This helps you achieve cost savings without compromising your product’s integrity.

2. Design Simplification

We reduce unnecessary complexity in your product designs. By eliminating redundant features or reducing the number of components, we make manufacturing faster and more efficient, which directly lowers costs.

3. Process Optimisation

Using advanced technologies like punch-laser combinations, we streamline the production process. This integration of multiple steps reduces secondary processes and saves both time and money.

4. Welding Alternatives

We identify opportunities to replace welding with forming if possible, minimising production time and material usage. Additionally, designing parts with tabs and slots reduces set-up times, leading to a more efficient manufacturing process.

5. Tooling & Assembly Jigs

Where appropriate, we design custom assembly jigs to speed up the manufacturing process. This reduces manual labour, shortens production time, and makes the process more cost-effective.

6. Waste Reduction

We evaluate designs to minimise material waste during production. By optimising nesting in sheet metal cutting and reducing offcuts, we help save on material costs while promoting sustainability.

Visit the Knowledge Base

Uncover more about sheet metal manufacturing processes, delve into our industry insights, and find answers to your frequently asked questions in the knowledge base.

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.