Metal fabricators for the Agricultural industry

Your sheet metal fabrication needs are unique. We understand that. Unifabs supports a number of agricultural machinery businesses, manufacturing parts for a variety of heavy machines and equipment.

When you choose Unifabs as your manufacturing partner, you can leverage our experience, knowledge, and expertise to help you create a product that will last for years to come. We’re proud of what we do. We want to help you create products that will deliver quality results and stand the test of time.

That’s why we’ve invested in the highest-quality, most reliable equipment and workforce, enabling us to provide you with the best manufacturing services for your agricultural machinery.

Cutting-edge manufacturing excellence

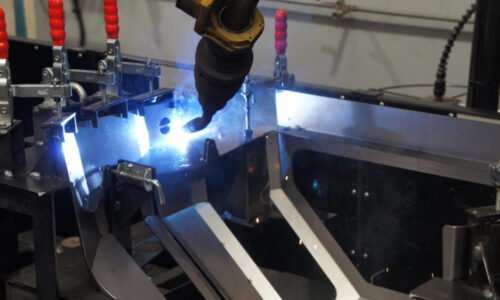

When you partner with Unifabs, you benefit from our wealth of experience along with state-of-the-art manufacturing technology. The last thing you need is a missing part stopping your assembly line. That’s why we invest in the latest technologies in profiling, metal bending, welding and powder coating, utilising a host of features including self-checking and setting, to reduce downtime and increase productivity.

Your brand is important, and we understand the need to manufacture your products consistently and repeatably. In addition to 12 manual welding stations, we also offer robotic welding for agricultural machinery products. Two state-of-the-art automated welding cells (single and twin cell set-up) deliver consistent high-quality welds and reduced weld times.

All parts are manufactured in line with our stringent quality standards, so you can rest assured that your product will be manufactured to the highest standards.

Agricultural machinery metal fabrication UK

At Unifabs, our metal fabrication team understand that your agricultural machinery products need to be high quality and robust, whether it be for a hedge cutter, harvester, tractor or baler.

Unifabs is perfectly positioned to be your agricultural machinery metal fabrication partner. Our facilities are centrally located in the Midlands, UK, enabling us to support agricultural machinery manufacturers with metal fabrication services quickly and efficiently nationwide.

Helping you yield better results

Our value-added manufacturing services are here to help you yield the best results. Our in-house industrial design engineers can support with value engineering and design for manufacture for agricultural machinery to ensure that your parts and products are manufactured in the most appropriate and cost-effective manner.

Collaborating closely with your own team, we can ensure your product designs are optimised for mass manufacture. So, whether it is a simple fabricated component or a complex assembly, our expertise can help give you the competitive edge.

Unifabs is experienced in the manufacture and supply of agricultural machinery parts such as:

- Casings

- Augers

- Booms

- Bracketry