Back in 2022, we introduced Jamie Hamilton as our newest CAD apprentice in a Q&A, where he told us about his typical day, his first impressions of Unifabs, and what he was most looking forward to during his CAD design apprenticeship.

Fast-forward to 2025, and Jamie has now completed his Level 3 Product Design and Development Technician apprenticeship, achieving two distinctions in his coursework. He is now a full-time member of the Unifabs design team and continues to grow in his role as a CAD Engineer.

We caught up with Jamie again to reflect on his journey and see how far he has come.

Q&A with Jamie Hamilton – 2025 update

Back in 2022, you described a typical day involving working with models, drawings, and ordering materials. How has your daily routine evolved since then?

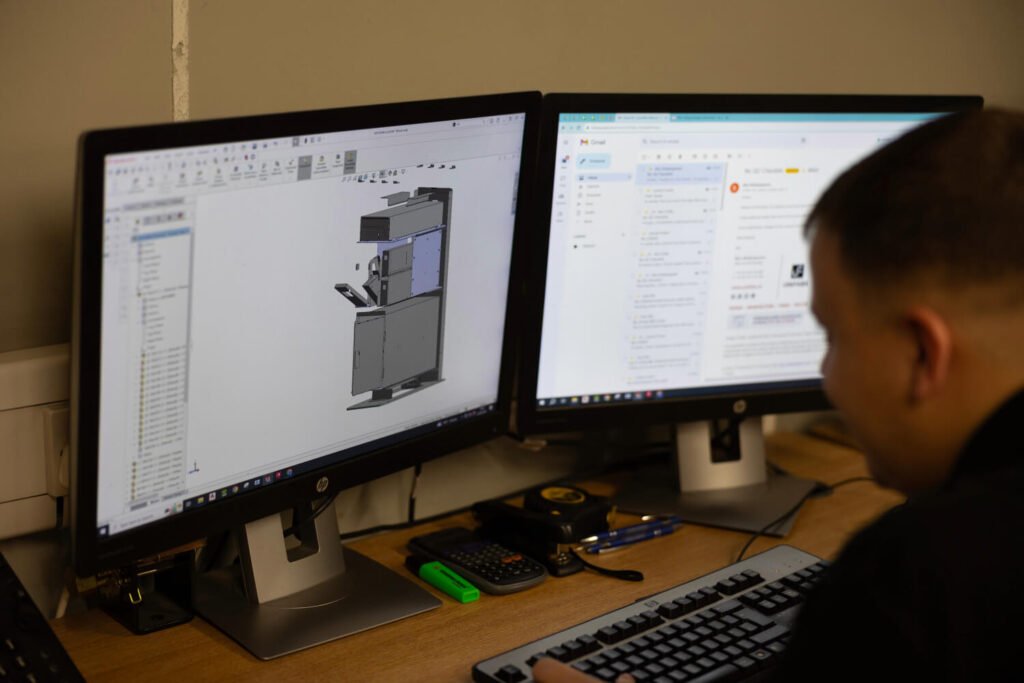

“That’s still a big part of what I do, but my role has become much more project-based and customer-focused. I now work more closely with clients – communicating via email and in person – which is something I really enjoy and shows how much I’ve progressed.”

You originally described your first impressions of Unifabs as ‘professional, organised and impressive’. How do you reflect on the company now you’ve completed your apprenticeship?

“I still stand by that, if not more so now. Over the past three and a half years I’ve seen Unifabs grow and invest in the right areas. It’s something I’m proud to be part of, and I’m excited about what the future holds here.”

What moment during your apprenticeship are you most proud of?

“Two things stand out. Achieving two distinctions in my coursework, and being offered a full-time position at Unifabs. That made all the hard work worth it.”

What’s next for you now that you’ve completed your CAD design apprenticeship?

“I’m looking forward to continuing my career here and developing further as a CAD Engineer. One thing I’ll be focusing on next is learning DriveWorks – a SolidWorks configurator we use to create automated design models. It’s a big part of our design process, so I’m excited to get involved with it.”

Learning through experience

Jamie’s apprenticeship gave him the chance to apply his learning to real engineering problems from day one. Early in the programme, he worked on adapting customer drawings and producing smaller fabricated parts. This soon progressed into full product designs, such as a bespoke point of sale display system that was developed from concept to completion.

Another key project was a precision checking fixture designed for a global manufacturer. The fixture helped ensure consistent product quality on the shop floor, and Jamie even created a supporting manual to guide its use. According to Technical Director Matt Grealy, apprentices are encouraged to take ownership of real projects early in their training, and Jamie consistently rose to the challenge.

“He got involved in projects that tested his technical thinking and communication skills,” Matt explained. “He was not just working in CAD, but seeing how those decisions played out in production.”

Tackling a complex fabrication project

Most recently Jamie has been working on a project for a new customer involving creating a process to build a very large fabrication that will be ongoing with several deliveries a week. It required Jamie to rework the customer’s CAD designs and plan how the structure could be manufactured in the easiest possible way, all while maintaining accuracy and build efficiency.

To make this possible, Jamie has designed specialist jigs, fixtures, and checking apparatus to ensure efficient manufacture, along with the addition of an overhead crane to aid in safe handling.

“Over the past few months, I have worked on a project to manufacture a very large chassis,” Jamie said. “This included two heavy fabrication jobs that needed breaking down to suit our manufacturing needs. It involved various things like new tables, jigs and fixtures, and the addition of an overhead crane. As I’m not from a fabrication background, this was an interesting project that helped me develop new skills in that area. A lot of work was, and still is, involved with this job – so it has been good for me to take the lead from a design point of view.”

Matt added that Jamie didn’t just work behind a screen on this project – he monitored builds closely on the shop floor, liaised with the fabrication team, and adapted designs as challenges came up. “This wasn’t just a CAD technician job. It required engineering judgement, hands-on co-ordination, and clear communication with production.”

CAD design apprenticeship

Looking back, Jamie said that what he enjoyed most about his CAD design apprenticeship was the variety. “No two days were the same, whether that was at college or Unifabs,” he explained. “Along the way I learnt new skills I didn’t expect, like 3D printing. Being around other engineers and customers has helped me pick up skills I now use regularly.”

One of Jamie’s biggest achievements was his academic result. “Achieving two distinctions during my apprenticeship is something I am proud of. Seeing the end result was amazing after all the hard work I put in. I was still fairly new to the industry when I first joined Unifabs, but since then I’ve come on leaps and bounds.”

He also highlighted the balance between work and study as a key part of his success. “Unifabs have been amazing from start to finish. They’ve always given me a good work-to-college balance. I could go to anyone here for help – whether it was college work or Unifabs-related – and they would give me their time and attention.”

When asked if there was anyone in particular that supported him on his apprenticeship journey, Jamie said that everyone had helped him progress, learn, and understand different aspects at Unifabs but gave special thanks to Shaun Fretwell, Ashley Roberts, and Matt Grealy in the CAD office, who helped teach him SolidWorks and support his development, as well as the team at North Warwickshire and South Leicestershire College (NWSLC) who guided him through the academic side of his apprenticeship. “I’d like to thank them all for helping me grow into the engineer I now am”, concluded Jamie (pictured below with Matt Grealy, left).

Supporting careers through apprenticeships

At Unifabs, we believe apprenticeships are more than just training – they are a vital part of building careers and future-proofing engineering skills. Jamie’s journey reflects what’s possible when hands-on learning is matched with real responsibility, strong mentoring, and a supportive team.

Matt Grealy said: “Jamie became a key member of the team even before finishing his apprenticeship. He’s proven that he has the capabilities of an experienced engineer. We’re proud of everything he’s achieved and excited to see how he continues to grow.”

Well done, Jamie – we’re proud to have you on the team.