Challenge

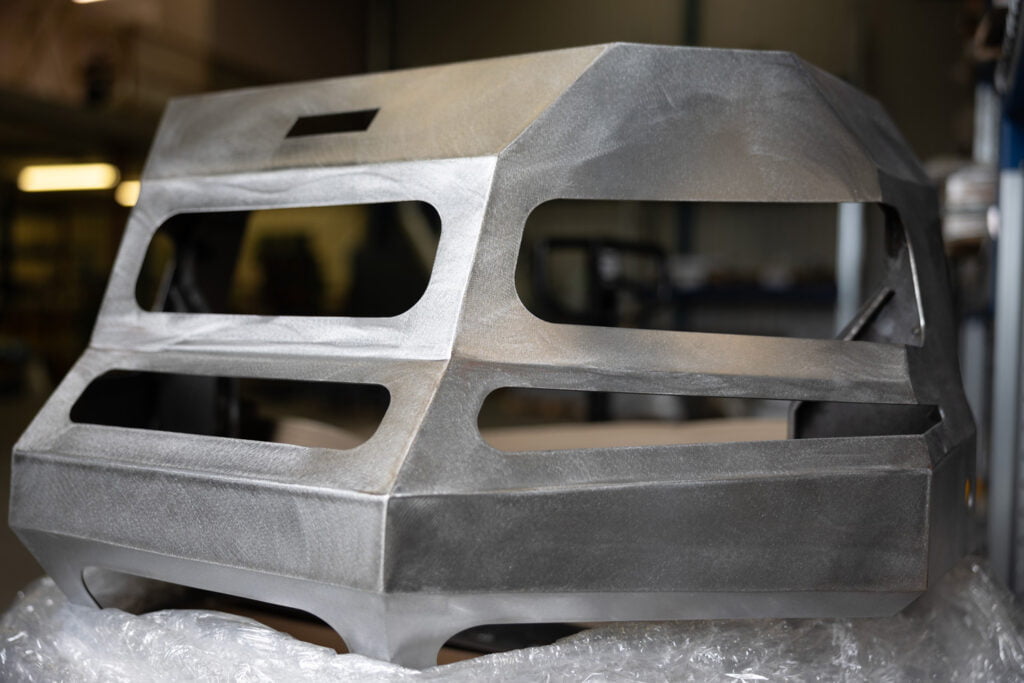

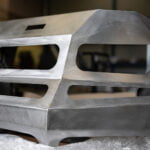

McConnel Ltd, wanted to source a cost effective and durable solution for a rear casing for their agricultural machinery. The rear casing formed part of a market leading remote controlled mower system. They were seeking a new solution due to supply and performance issues with the original composite part.

Solution

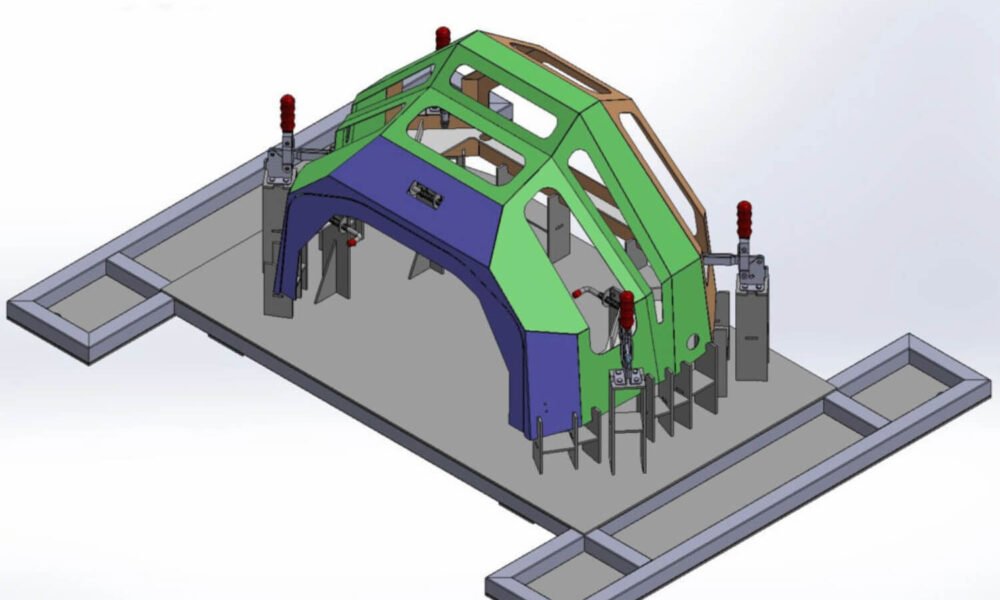

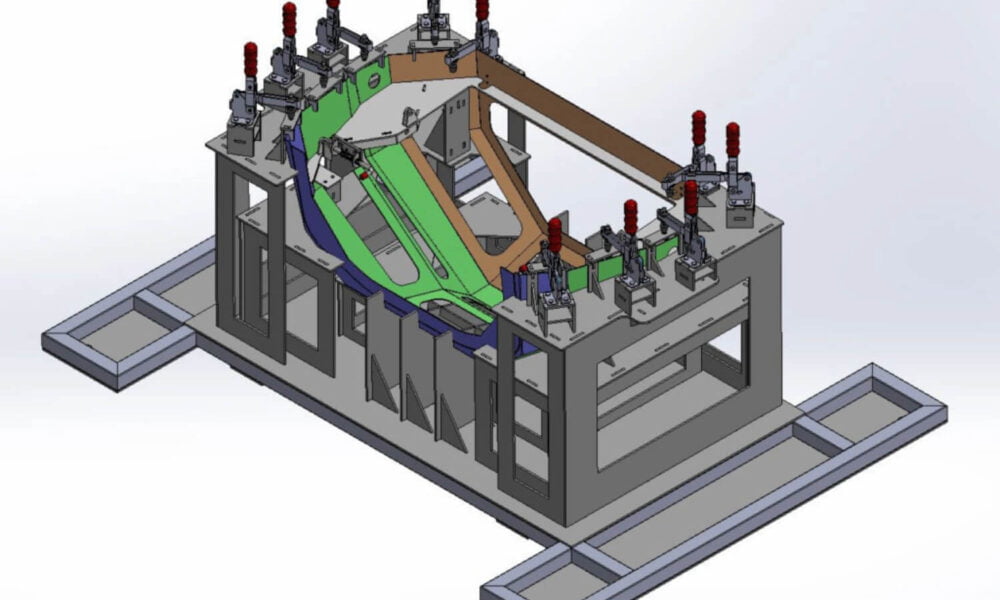

Unifabs’ experienced in-house design team reviewed the designs and, after closely consulting with the customer, altered the makeup of the part to allow for cost-effective and repeatable manufacturing.

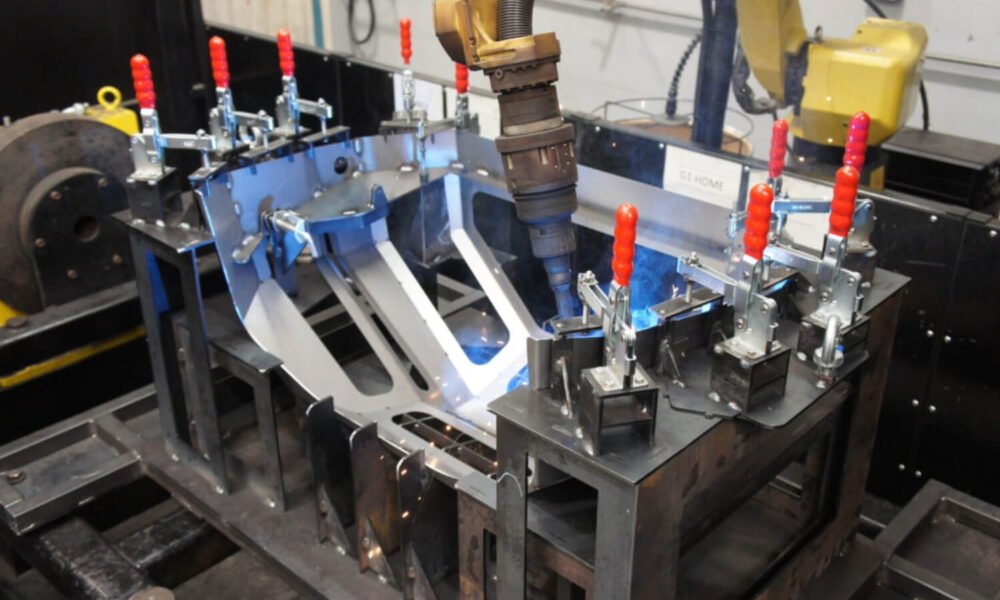

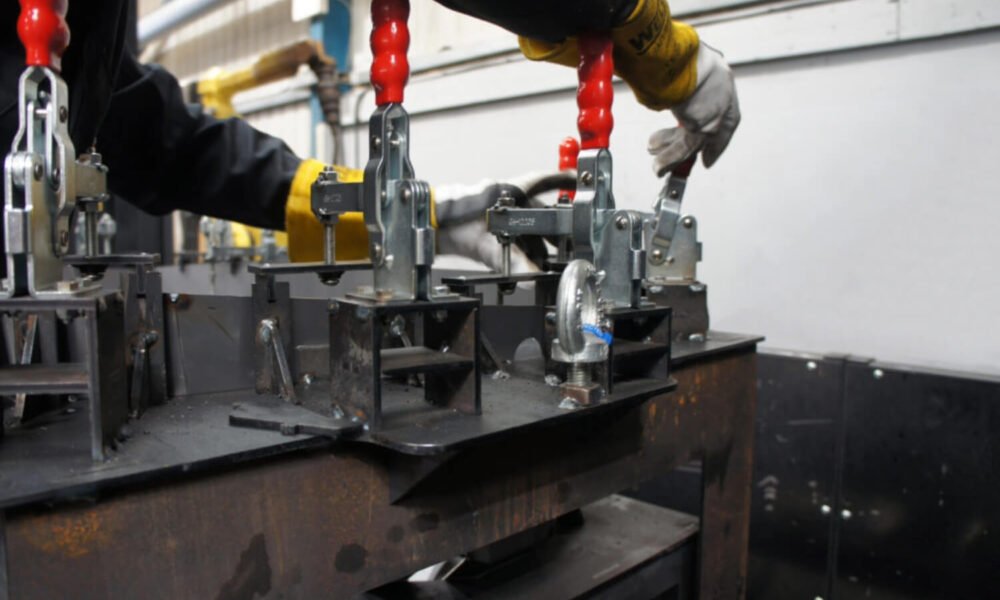

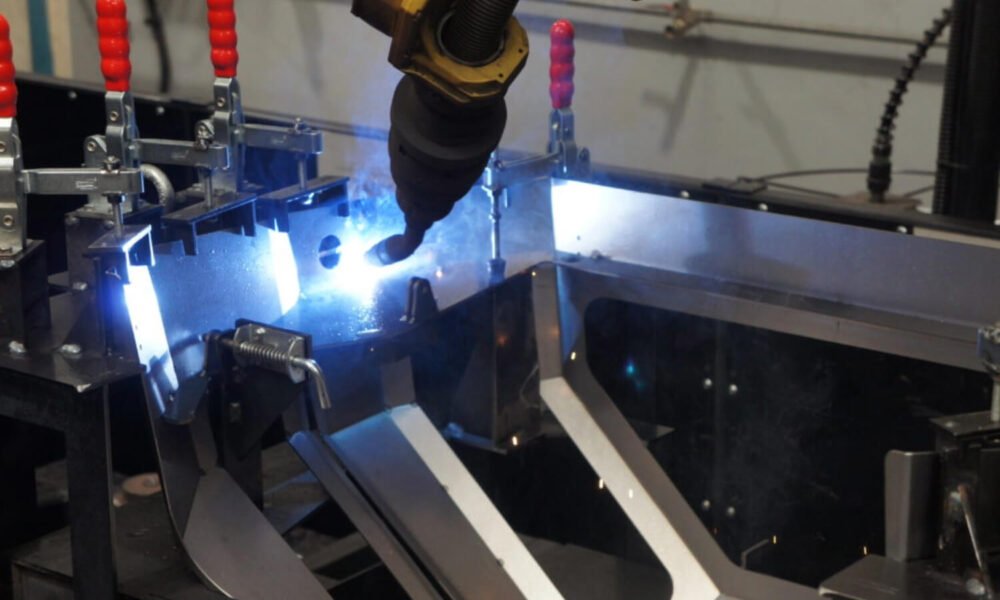

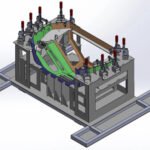

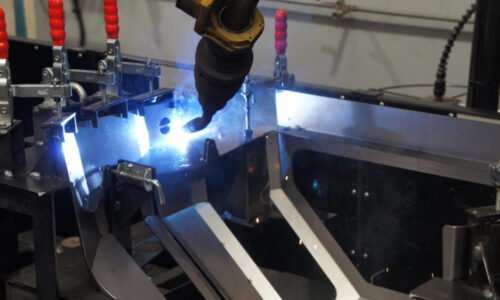

Two operators were initially required to fold and form the complex part. Following the design review, we reduced it to just one operator. Due to the complexity of the folding process, we added break-off tabs to aid the operator and speed up folding. To ensure repeatable consistency, jigs were designed for integration with the robot welder, allowing for the part to be fully welded via the robot. A prototype was produced and a further opportunity to remove a visible weld was identified.

Result

Unifabs were able to successfully replicate the composite product in a cost-effective manner producing a much more durable casing, and ultimately enhancing the end-product.

Team Feedback

Utilising jigs and robotic welding, we were able to transform the end product and solve supply and performance issues for our customer.

Project Manager

Services & Solutions from this project

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.