Metal forming services at Unifabs

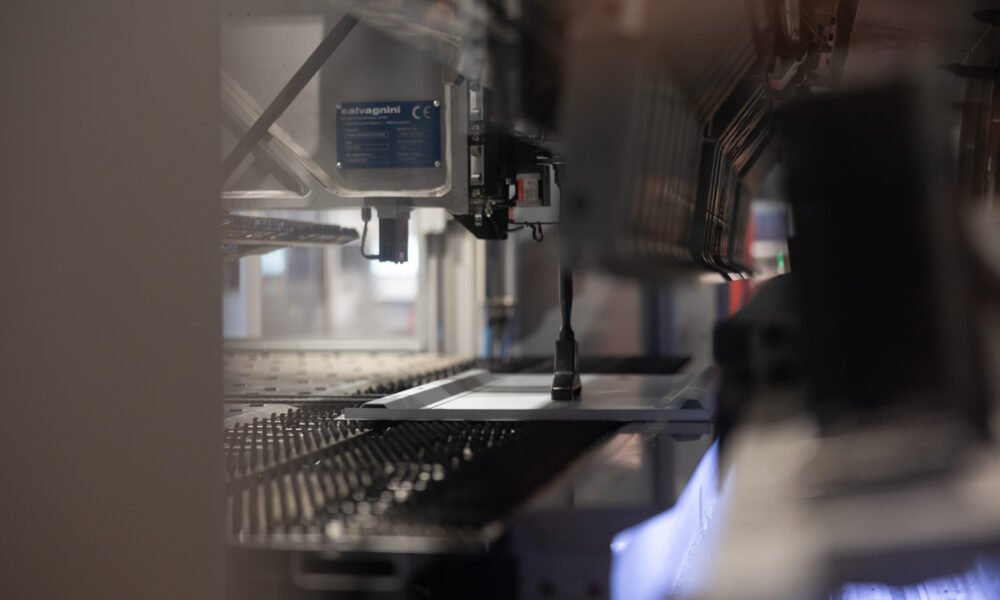

At Unifabs, we are equipped with two advanced Salvagnini panel benders, capable of bending materials up to and including 3mm in thickness. This technology allows us to provide precision metal forming services that set the standard for efficiency and accuracy.

What is a Salvagnini panel bender?

Where a traditional press brake uses a single tool from above to force the material into a lower ‘V’, creating the form, a Salvagnini Panel Bender can apply an up or downstroke, with independent tools, while a manipulator moves the part into position.

This automated process eliminates the need to change tools to create a different form, and the requirement to flip the part to bend in a different orientation.

Productivity and flexibility in metal bending

The features of a Salvagnini P2 deliver obvious benefits in terms of productivity when compared to conventional bending on a press brake through its automatic bending and handling cycles.

Combining this productivity with the P2’s flexibility in terms of universal bending tools, this technology can deliver up to 17 folds per minute with extreme accuracy.

Adaptive automation in action

With its integrated advanced sensors, the Salvagnini P2 measures the actual thickness, size and strength of the material and detects any variation. The data is fed into the bending formula which defines the correct force required to create the bend, guaranteeing precise and repeatable bending for a quality finished product.

Unlocking design and commercial improvements

With the capabilities the Salvagnini panel bender offers, Unifabs helps customers to unlock opportunities through refinements in design, ensuring products are produced in the most efficient and cost effective manner. Our metal forming services, using advanced Salvagnini panel bending technology, may enable us to combine multiple parts into one fully folded piece or eliminate additional processes such as riveting and welding. These changes to how products are produced deliver visible advantages in terms of product appearance, alongside commercial benefits, allowing us to remove processes, reduce lead times and produce high quality parts for less.

Materials

- Mild Steel

- Stainless steel

- Aluminium

Capabilities

Sheet size

Maximum length of part:

2500 mm

Material thickness

up to and including 3 mm

Technology

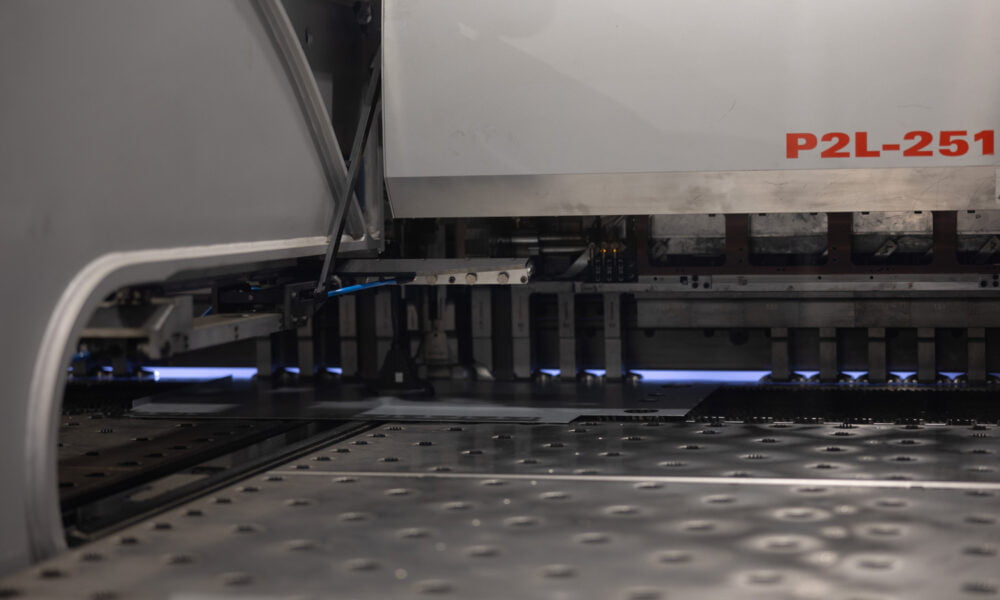

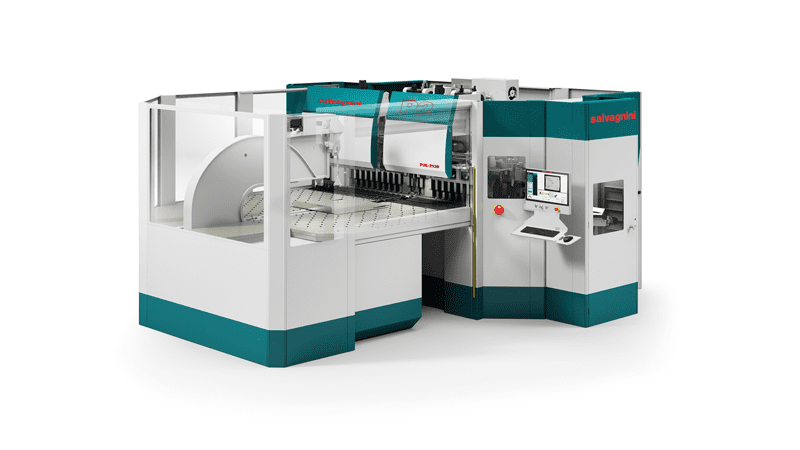

- Salvagnini P2-2520

- Salvagnini P2L-2120

Our Salvagnini Panel Bender Capabilities

Flexible and intelligent automated panel bending offering precision and repeatability.

Salvagnini P2-2520

Salvagnini P2L-2120

The P2 is the ultimate Salvagnini panel bender, natively combining productivity, with its automatic bending and handling cycles, flexibility, with its universal bending tools, and versatility, with its ability to perform both positive and negative, flattened and radius bends. Equipped with an automatic blank holder, the P2 doesn't require re-tooling and completes an average of 17 bends per minute. The P2L-2120 model can fold material up to and including 2mm thick, while the latest addition to our forming centre, the P2-2520, extends this capability to material up to 3mm thick.

Visit the Knowledge Base

Uncover more about sheet metal manufacturing processes, delve into our industry insights, and find answers to your frequently asked questions in the knowledge base.

Design to delivery, adding value at every stage

Discover how we partner with businesses to add value and bring products to life.