We’re always looking for ways to enhance our offering, streamline processes, and deliver better outcomes for our customers. Our latest investment—a Max Photonics ZXMA1-65 handheld laser welding cell—adds a new dimension to our fabrication capabilities, particularly in aluminium welding, a technically challenging area where quality and control are crucial.

This upgrade supports our strategic focus on innovation and in-house capability. By integrating laser welding into our existing range of services, we further strengthen our ability to take projects from concept to completion—delivering high-precision, clean-welded assemblies across a wider range of materials.

What is Laser Welding?

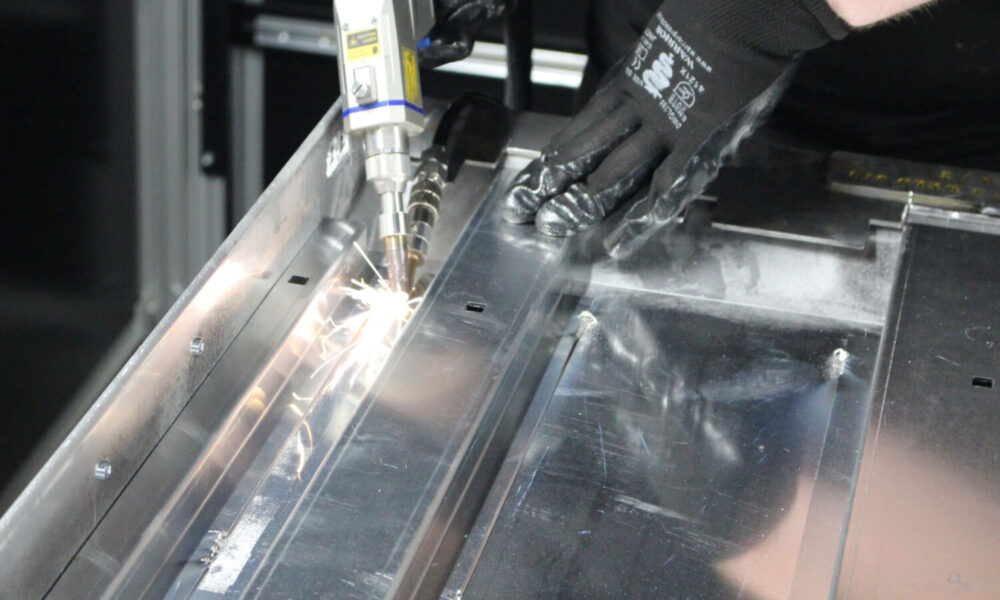

Laser welding is a non-contact process that uses a high-energy laser beam to produce extremely precise, narrow weld seams with minimal distortion. It’s fast, accurate, and ideal for materials that are difficult to weld using traditional methods—like aluminium.

Compared to MIG and TIG welding, laser welding offers:

- Higher speed and repeatability

- Minimal heat input and less warping

- Exceptional weld quality and aesthetics

- Reduced need for finishing or rework

With growing demand for lightweight, complex, and tight-tolerance fabrications—especially in industries such as automotive, electronics, and technology enclosures—laser welding gives us the edge in both quality and efficiency.

Solving the Aluminium Welding Challenge

Aluminium welding is known to be technically demanding due to its high thermal conductivity, oxide layer, and sensitivity to heat and contamination. That’s why laser welding is an ideal solution: it delivers clean, consistent welds without compromising the integrity of the material.

The new Max Photonics MA1-65 system gives us new flexibility in how we approach aluminium welding tasks, ensuring we can maintain strict quality and delivery standards repeatably—key priorities for our customers.

The system includes a wire-feed unit, allowing us to handle a wider variety of joint types and part thicknesses—including up to 5.5 mm in aluminium, and 6.5 mm in stainless steel, and mild steel. This breadth of capability means we can deliver strong, clean welds across a wide range of materials and geometries.

Combined with air-fed Kapio laser welding helmets, a fully enclosed welding bay, and trained operators, the setup ensures high-quality results in a safe, controlled environment.

Supporting Our Broader Welding Capabilities

This latest investment complements our existing welding services, which include:

- Manual MIG and TIG and spot welding, performed by skilled fabricators

- Robotic welding, ideal for repeatable, high-volume production

- Advanced jigs, fixtures, and inspection tools for consistency

Laser welding is not a replacement—it’s an addition. It gives us another tool in our fabrication toolkit, particularly where cosmetic appearance, precision, and aluminium compatibility are essential.

A Complete In-House Manufacturing Solution

At Unifabs, we pride ourselves on being more than a subcontractor. We are a true manufacturing partner, offering a fully integrated service that includes design support, laser cutting, CNC bending, welding, assembly, and finishing—under one roof.

Adding this new welding technology allows us to better support customers across sectors who are looking for high-quality welded components delivered quickly and reliably. It’s also part of our wider vision: investing in automation, improving internal capability, and removing the need for outsourcing wherever possible.

State-of-the-Art Laser Welding Technology

Our new laser welding cell includes:

- Max Photonics ZXMA1-65 laser welder with wire feed

- 4m x 3m laser-safe enclosure with integrated power, lighting, and interlock systems

- Roofing module and optical viewing window

- Kapio air-fed laser welding helmets

The system has been installed and commissioned, and our operators have completed comprehensive training in its safe use. It is now supporting customer orders where aluminium welding and precise finish quality are critical.

Want to Know More?

If you have projects that could benefit from laser welding, or are looking for a reliable partner for aluminium welding and precision fabrication, get in touch. Our team would be happy to explore your requirements and recommend the best solution. Read more about laser welding in our FAQ’s.